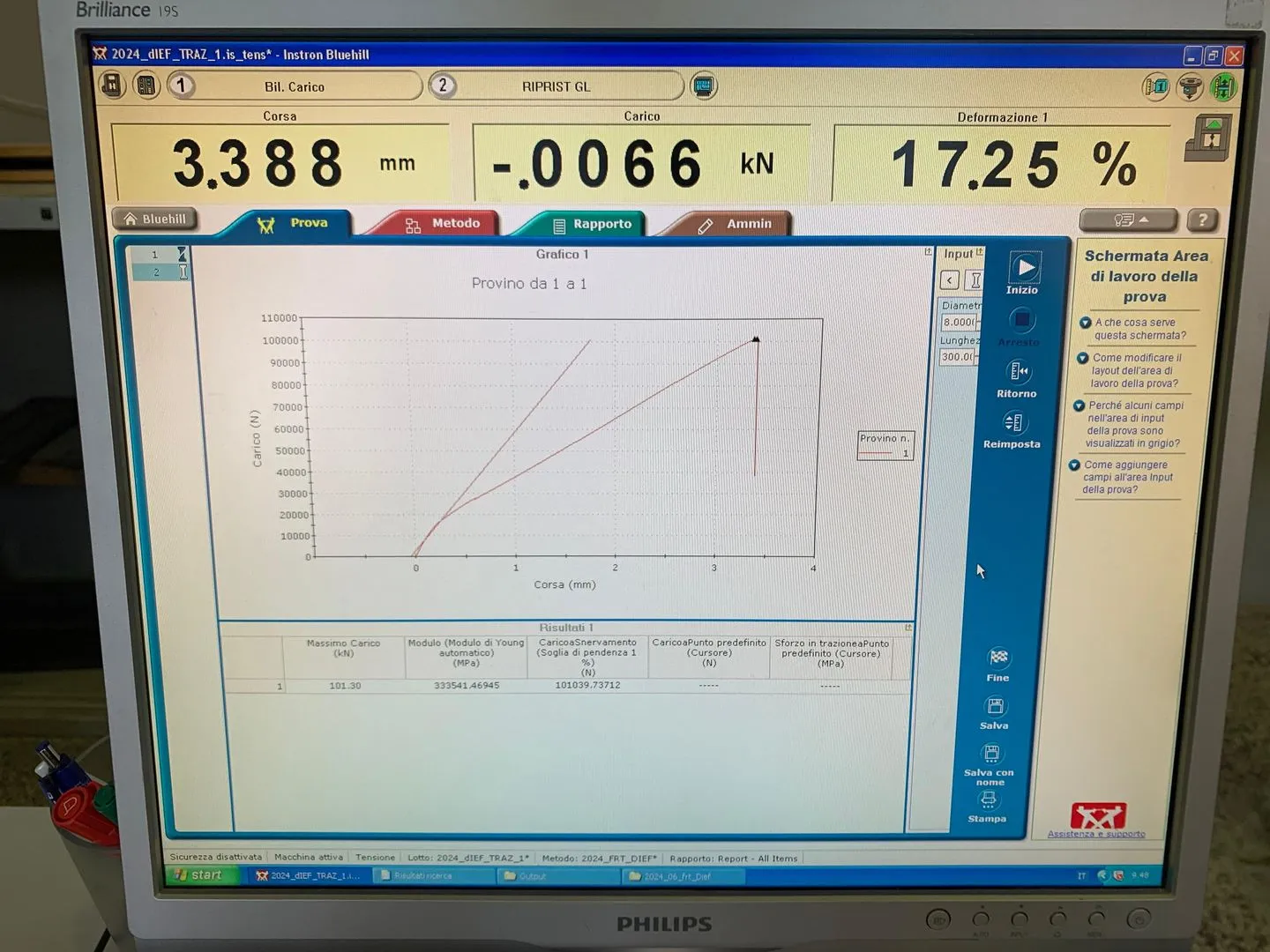

Tensile test for FR-24's chassis

In order to participate in the competitions, it is mandatory to submit documentation that certifies the safety of the chassis. For this reason, in collaboration with the Structural and Materials Testing Laboratory of the DICEA (Department of Civil and Environmental Engineering) located in Santa Marta, tensile tests were carried out on specimens made using the same tubes as our spaceframe chassis. These tubes are made of two types of high-strength alloy steel, as required by the competition regulations, to validate the mechanical strength of the welds at the most structurally critical joints.

Both butt-welded and cross-welded specimens were tested. Using the appropriate testing machine, and applying the required tensile forces, we were able to demonstrate the actual strength of the weld beads. This allowed us to successfully complete all the required documentation for the judges and certify that the chassis is fully compliant and safe.