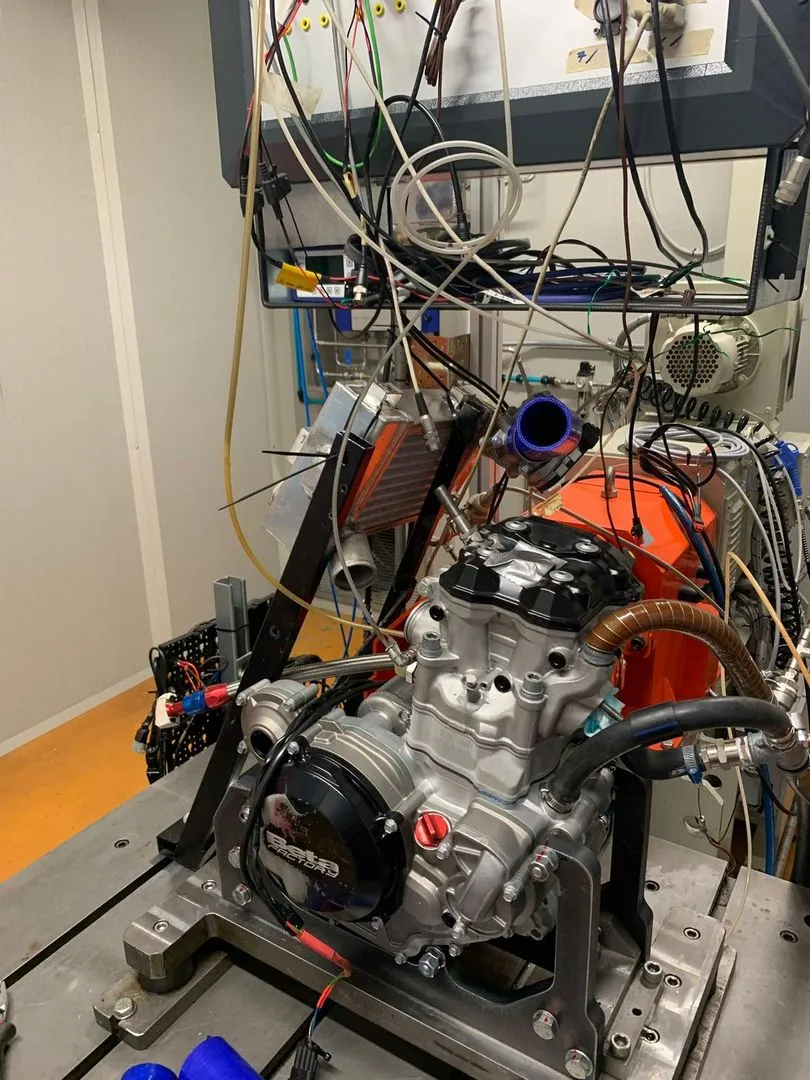

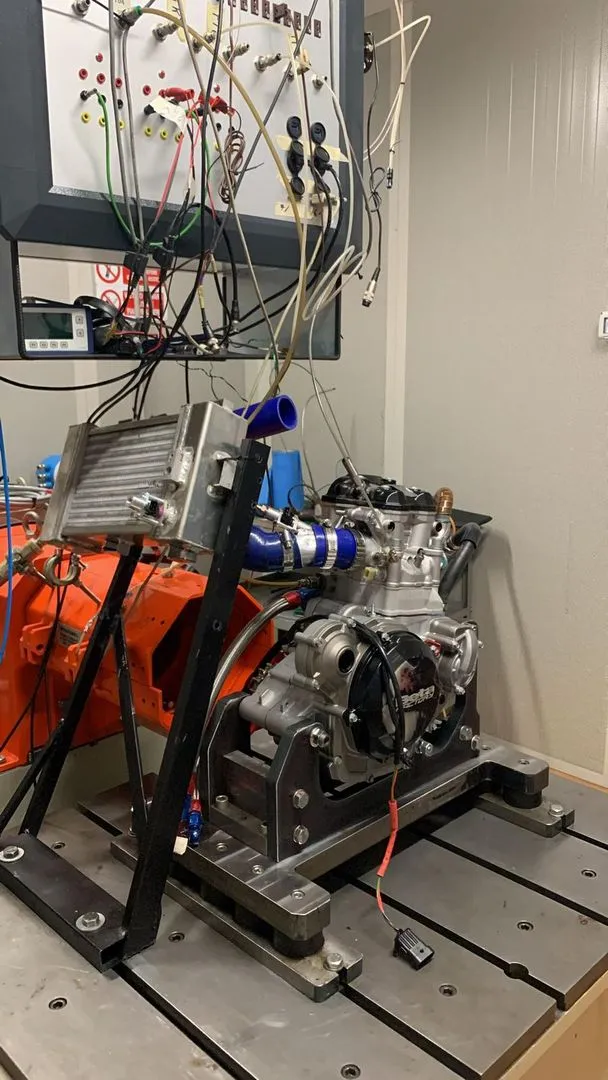

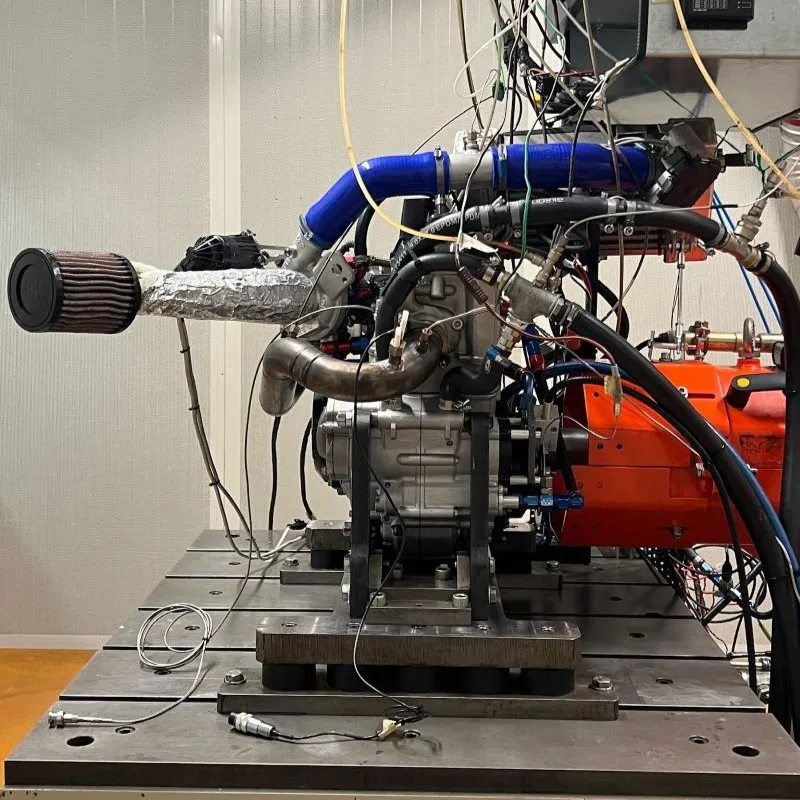

Beta 480 turbo engine test rig

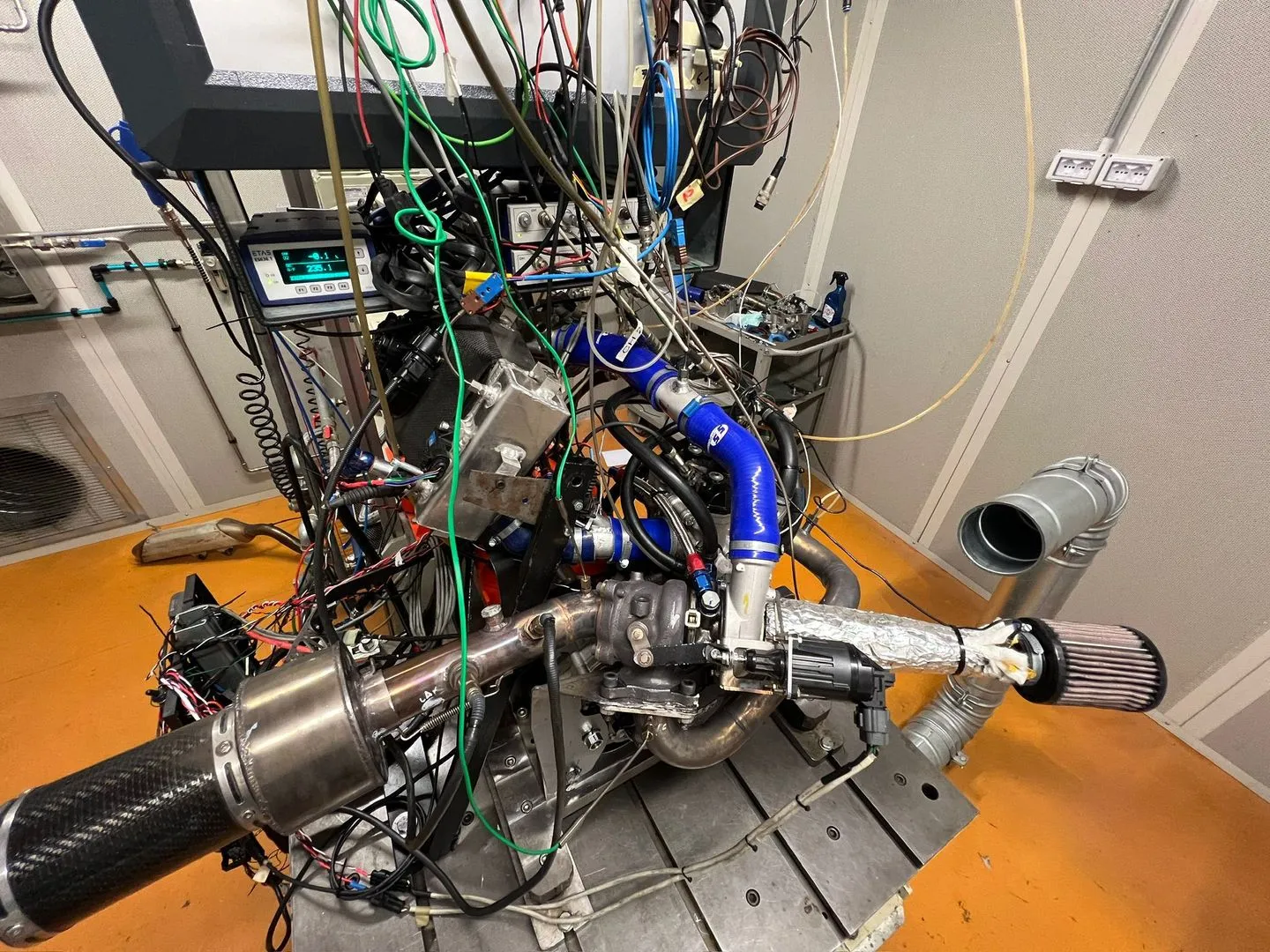

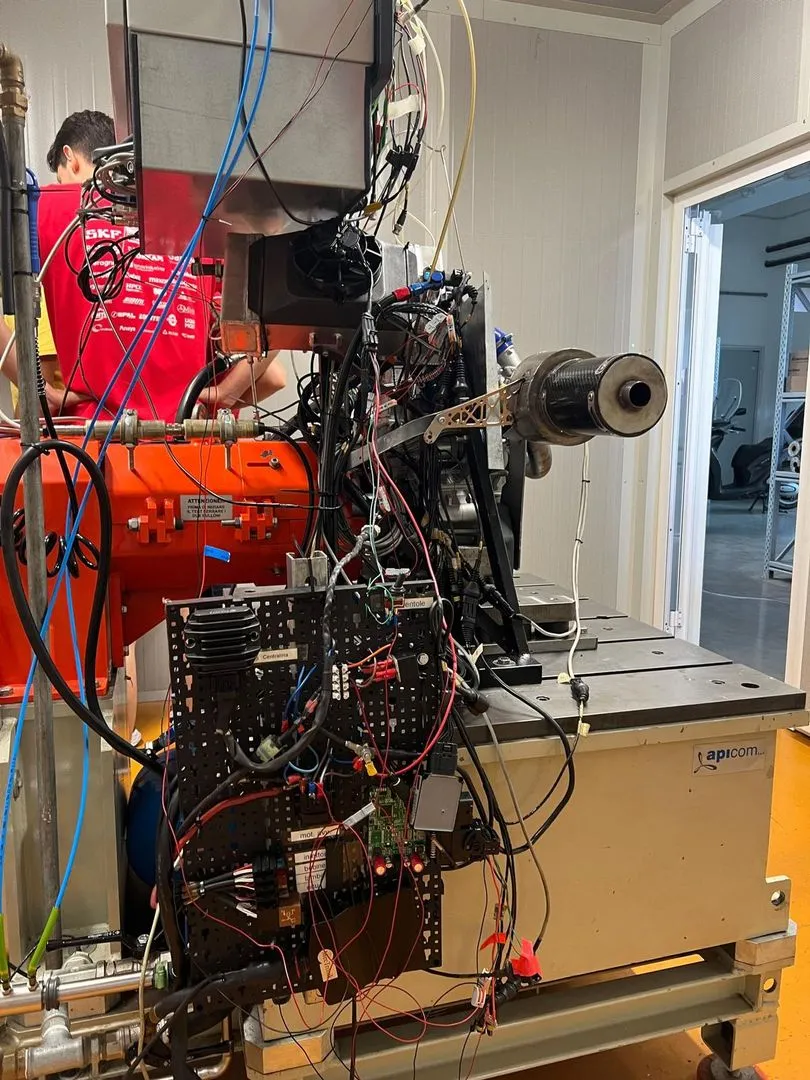

The engine is one of the fundamental components of our prototype, and making it both high-performance and reliable is crucial for achieving competitive results. For this reason, with the invaluable support of Eng. Luca Romani, Sandro Raspanti, and the entire LInEA laboratory team, we launched a dynamic engine-bench testing campaign to verify the main turbocharging components and develop an advanced map for the new Beta 480 turbocharged engine.

The LInEA laboratory, specialized in research and development of internal-combustion engines, is equipped with experimental test benches that enable in-depth analyses under controlled conditions.

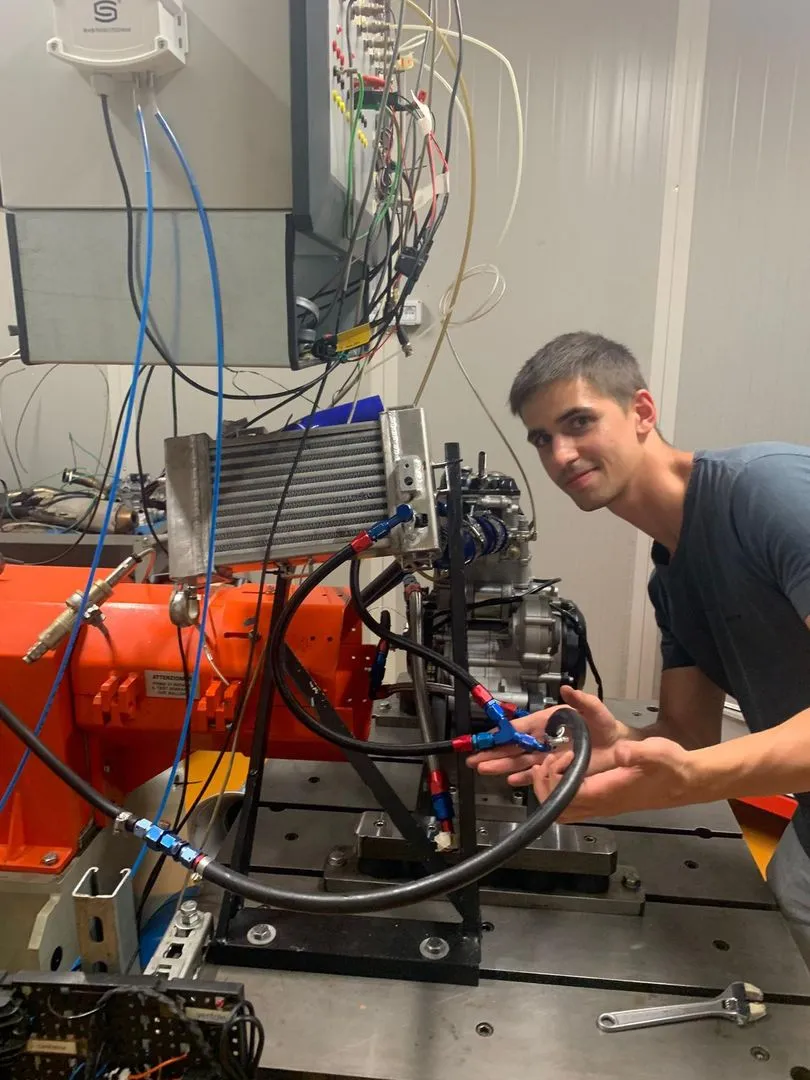

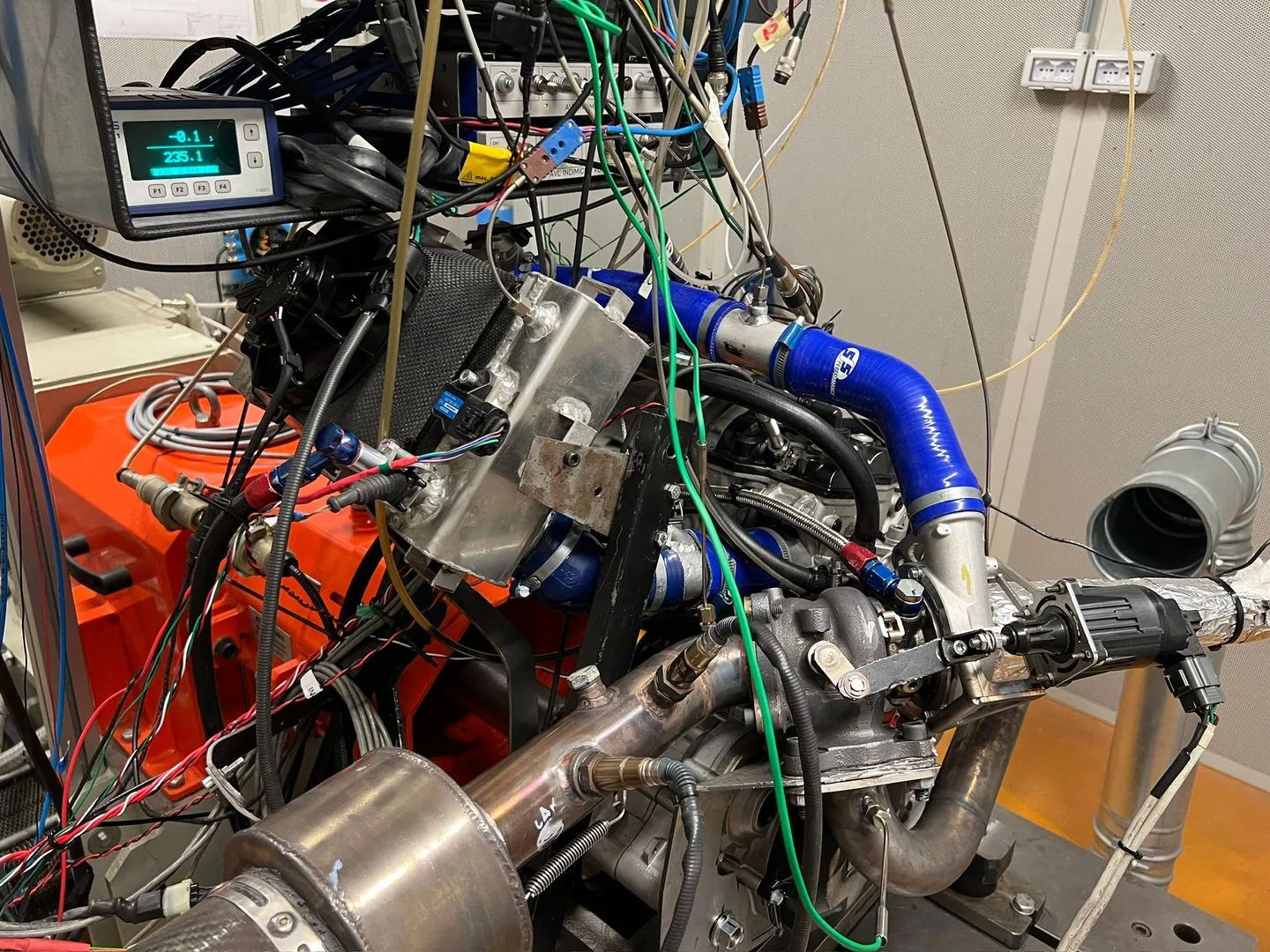

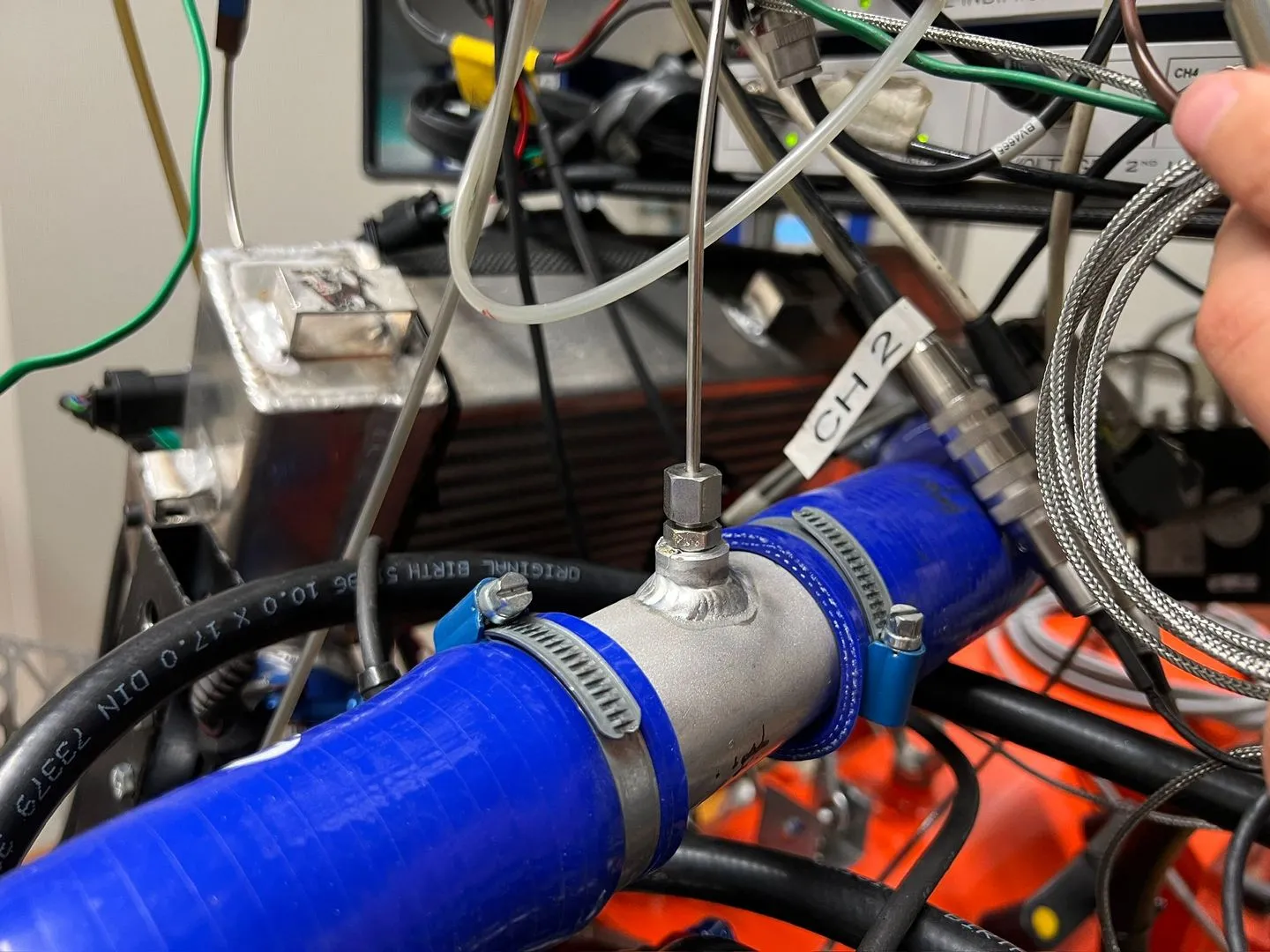

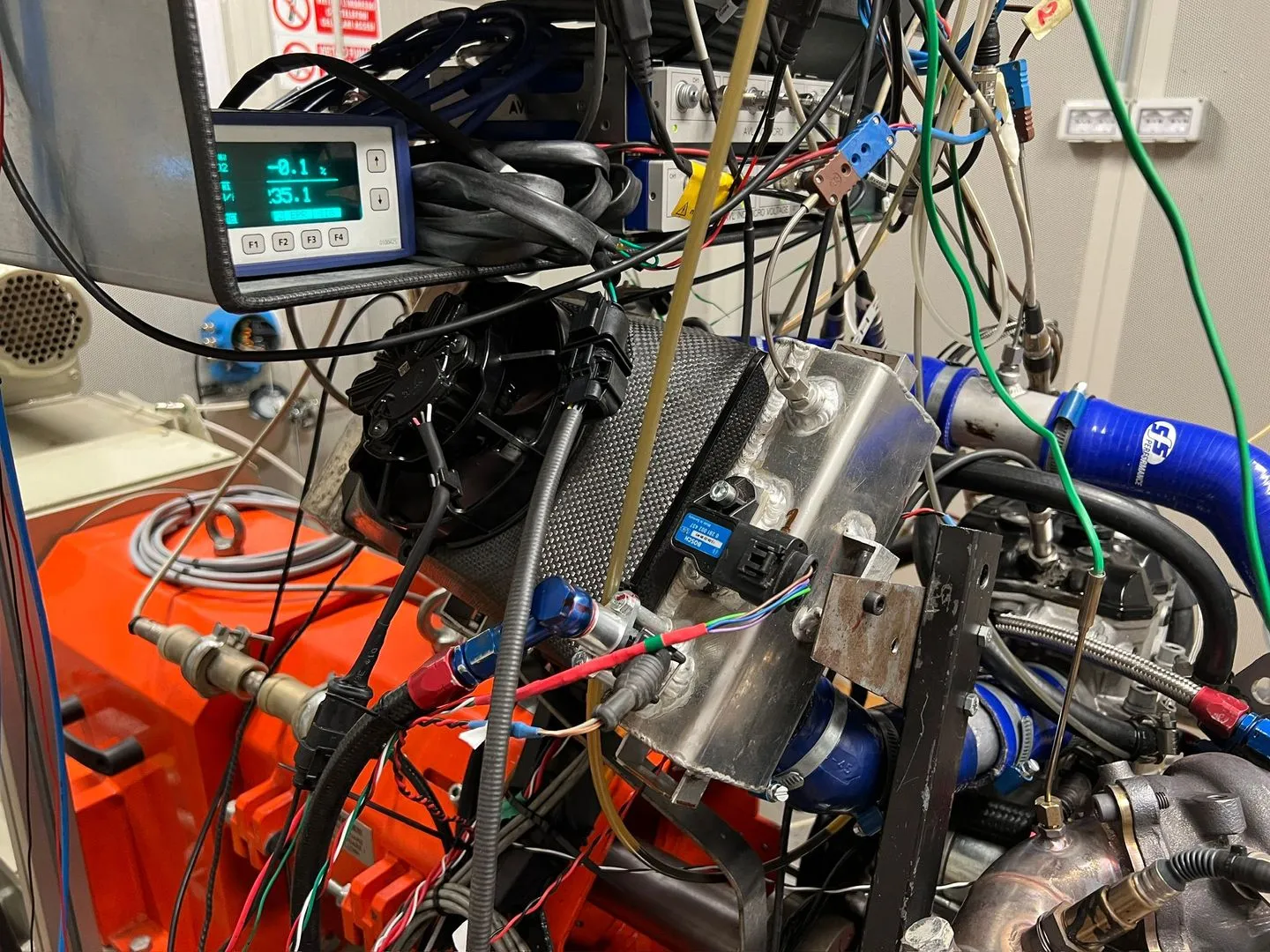

The initial phase involved assembling the engine to replicate exactly the configuration installed in the car. Sensors were placed at the most strategic points for both the ECU data acquisition and the bench instrumentation. A custom wiring harness compatible with the new MKE7 ECU supplied by Mectronik was also made; this ECU offers advanced functions and greater configurability compared with the previous model.

Next came the core bench-testing phase: correct timing was set, followed by a series of full-load runs, analyzing every relevant parameter to optimize efficiency and maximize the power-plant’s performance.

The engine team worked with dedication and expertise to develop an effective calibration and gain new insights into turbocharging, making a decisive contribution to the project’s technical growth.