Braking system

The braking system is slowly taking shape. It is divided into two systems, one for the front axle and one for the rear, as required by the regulations. This configuration makes it possible to maintain maximum safety even in the event of a fault or leak in the system; this is very important for the safety of our pilots, as they must be students.

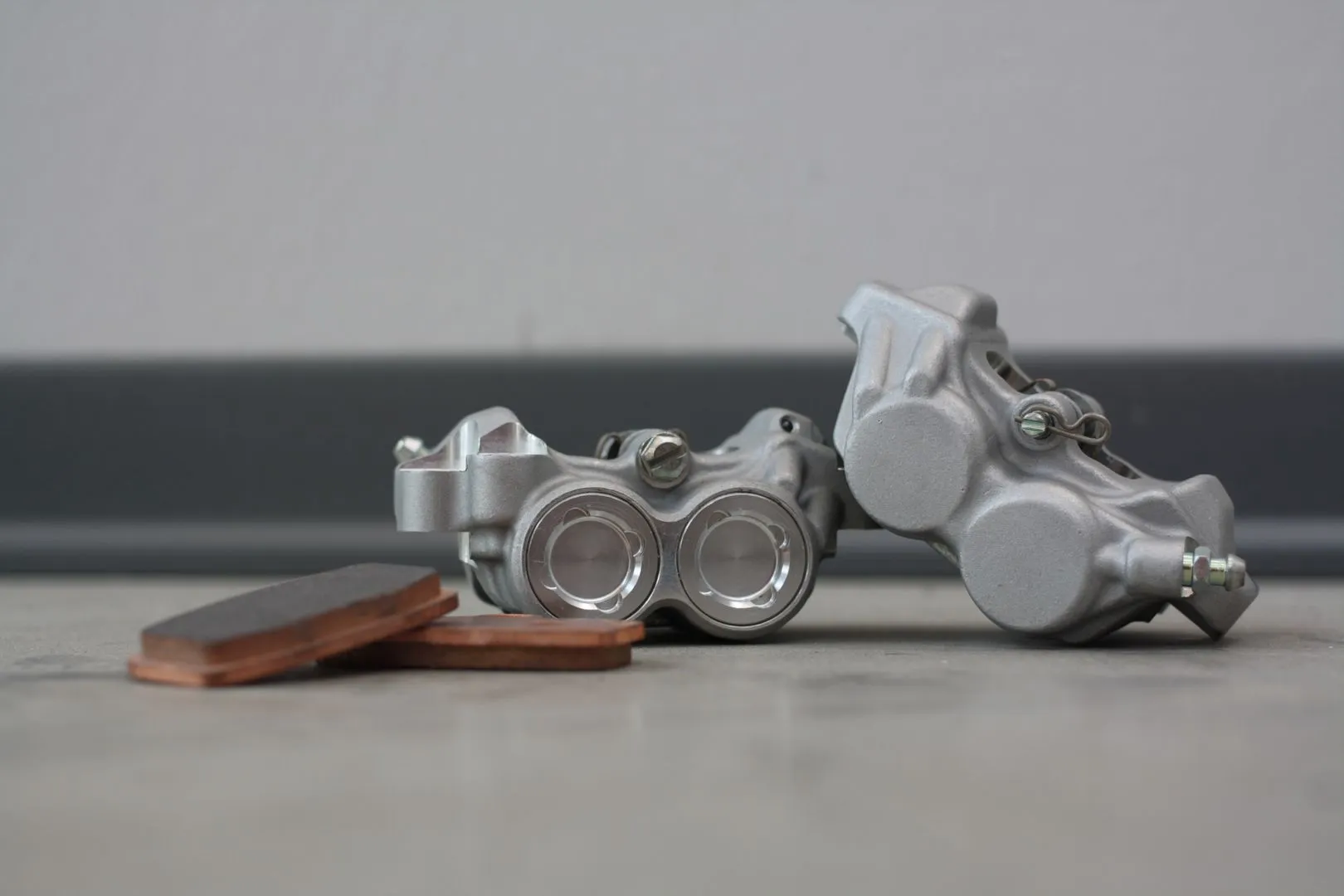

Each system therefore has its own pump, but both have the same pump diameter. All four calipers are the same, with radial mounts and 4 opposed pistons. They are made of cast aluminium, to achieve an excellent stiffness-to-weight ratio that allows for excellent performance and precise braking despite the low mass. The pistons, on the other hand, are made of phenolic resin, full, to allow reduced response times while maintaining the necessary rigidity, despite the system pressure reaching a few tens of bars. The pads used are made of sintered compound, which is more efficient than organic compound pads.

This year the brake discs, which are floating, have been designed by the group manager Ilaria Tanini, with a different geometry for the two systems; they both have the same thickness but a different diameter, larger for the front system, so as to better exploit the load transfer during braking and the friction between the tyres and the road. During the design, it was decided to insert the function of the phonic wheel directly into the brake discs, in order to reduce the weight of the unsprung masses and to insert an innovative and unusual solution into the car, given that one of the team’s main objectives is to find new solutions and functions for the car.

The person in charge of the braking system, Riccardo Del Carria, has designed the entire system in such a way as to obtain the right distribution of braking and a braking sensitivity that does not fatigue the driver during the braking phase, while maintaining the correct modulability of the pedal. These measures make deceleration more precise and comfortable. In any case, both the Balance Bar on the brake master cylinders and the proportional valve on the rear system have been fitted so that the braking distribution can be varied according to the rider and his preferences, and to calibrate and set the entire system correctly.

We are looking forward to installing all the components and pipes in the car and testing the system during the test days!!!

We would like to thank:

- Formula Italy for the brake calipers and pads, a company based in Prato (FI) that designs and manufactures calipers, brake discs, suspension, wheels, suspension for MTBs and motorbikes.

- Gieffe Racing for pipes and various fittings

- ITAparts for brake discs